| Functional tests of railcar brake systems

Measurement & Test of brake forces, system pressures as well as other measurement quantities

overview

The precise and accurate determination of acting brake forces as well as additional important quantities (i.e., pressures) of the brake system of railcars is of highest importance. The safe transport of persons and goods is of utmost priority. Besides a required test of the brake force system during commissioning such measurement system assisted testing procedures should be carried out during or after maintenance and retrofitting. Although brake systems in good working conditions are the requirements for a safe railcar operation, unfortunately regular time interval-based measurement systems supported checks are still the exception. The typical approach of operational personal carrying out daily operational checks such as a brake system test during standstill or an overall system with a drive and brake approach are not sufficient. Many possible failure modes, especially in system components are not discovered. In addition a condition based maintenance is not possible with these approaches. Furthermore, the more and more increasing pressure for cost efficiency and cost reduction, leads to the questionable practice of increasing the maintenance intervals. If this is solely based on an increase of maintenance interval durations the evolution of critical errors is only a matter of time. The overall safety level of the operated railcar decreases and eventually devastating accidents could occur. Nevertheless, an approach based on independent measurement systems can eventually lead to a win-win situation. The possibility to determine important brake system characteristics (i.e., individual force-time profiles or brake system pressures) permits: The precise and accurate determination of acting brake forces as well as additional important quantities (i.e., pressures) of the brake system of railcars is of highest importance. The safe transport of persons and goods is of utmost priority. Besides a required test of the brake force system during commissioning such measurement system assisted testing procedures should be carried out during or after maintenance and retrofitting. Although brake systems in good working conditions are the requirements for a safe railcar operation, unfortunately regular time interval-based measurement systems supported checks are still the exception. The typical approach of operational personal carrying out daily operational checks such as a brake system test during standstill or an overall system with a drive and brake approach are not sufficient. Many possible failure modes, especially in system components are not discovered. In addition a condition based maintenance is not possible with these approaches. Furthermore, the more and more increasing pressure for cost efficiency and cost reduction, leads to the questionable practice of increasing the maintenance intervals. If this is solely based on an increase of maintenance interval durations the evolution of critical errors is only a matter of time. The overall safety level of the operated railcar decreases and eventually devastating accidents could occur. Nevertheless, an approach based on independent measurement systems can eventually lead to a win-win situation. The possibility to determine important brake system characteristics (i.e., individual force-time profiles or brake system pressures) permits:

- a condition based monitoring is possible whereby the time-of-life of the individual subsystem is determined and only system components are exchanged which require it

- an overall system safety level increase, as a time-discrete monitoring of the system and its components is carried out

The measurement and test system PRODAT BKM has been skillfully engineered in order to suite these requirements and to help to make public and non-public railways safer. It has been used for many years by PRODAT and its customers. The system supports a large number of different railcar brake types (i.e., disk or block types) and follows a modular system architecture concept. It either replaces the wear components or is integrated in between the wheel and wear component. Acquired are not only directly acquired data time series profiles of the individual acting forces (time-force-profiles) but also of important additional quantities, such as different brake system circuit pressures. In addition customer specific additional signals can be easily integrated into the system. All required measurement data is viewed, saved, archived and gathered in a documenting protocol. Customers can either buy the measurement system, rent a system or can use PRODATs measurement services at the customer site.

Application variants

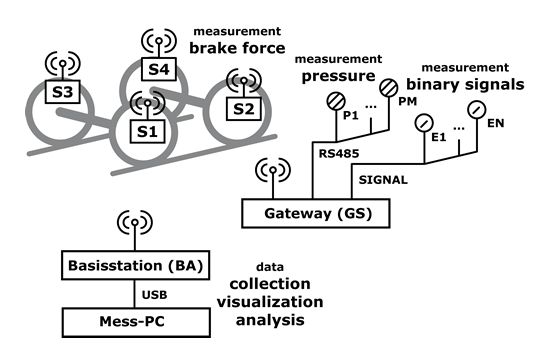

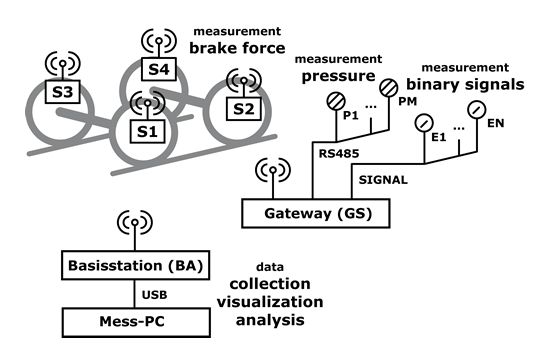

The typical system configuration of the mobile brake force measurement system PRODAT BKM include:

- cable-based brake force measurement & test system – PRODAT BKM C (‘cable’)

- wireless brake force measurement & test system – PRODAT BKM W (‘wireless)

Constructional variants exist for different brake types and include:

- air brakes (‘block brake’)

- disc brakes

- customer specific brake types

Customer options for a system acquisition

Wireless brake force measurement & test system PRODAT BKM-W

The measurement & test system PRODAT BKM-W permits the wireless determination of important brake force system quantities of railcars, such as the acting forces or pressure in the hydraulic brake circuits. If used the number of detectable brake system failure modes is greatly increased, as also individual subsystem functionality can be tested by using an independent and external measurement system (i.e., lockings, pressure losses). A quick maintaining reaction is possible and the overall safety level is increased. The measurement system is based on PRODATs modularized internetworked construction kit and framework PRODAT SENET. It architecture allows very flexible system configurations and besides existing sensors and sensor systems customer specific requirements can be easily solved. Besides using of the force or pressure sensors, digital signals can be acquired if needed. Other possible quantities include environmental workshop conditions such as humidity or temperature. Especially the wireless system approach greatly simplifies the system usage, as typically a large number of fast braking long cables is not required (in difference to a number of different solutions on the market). By employing PRODAT SENET in the PRODAT BKM-W system it supports either a standalone operation or an integration into existing test & measurement systems and/or infrastructure. The individual measurement system components, especially the sensors are battery operated, and support runtimes of 12h and beyond (longer duration in dependence of the user specific usage cycle are possible). The wireless communication distance with line-of-sight is typically 100m. In typical operation conditions, i.e., in the workshop with metal surroundings and when positioned at the bogies the communication distances can decrease to typically 20 to 30m. The measurement & test system PRODAT BKM-W permits the wireless determination of important brake force system quantities of railcars, such as the acting forces or pressure in the hydraulic brake circuits. If used the number of detectable brake system failure modes is greatly increased, as also individual subsystem functionality can be tested by using an independent and external measurement system (i.e., lockings, pressure losses). A quick maintaining reaction is possible and the overall safety level is increased. The measurement system is based on PRODATs modularized internetworked construction kit and framework PRODAT SENET. It architecture allows very flexible system configurations and besides existing sensors and sensor systems customer specific requirements can be easily solved. Besides using of the force or pressure sensors, digital signals can be acquired if needed. Other possible quantities include environmental workshop conditions such as humidity or temperature. Especially the wireless system approach greatly simplifies the system usage, as typically a large number of fast braking long cables is not required (in difference to a number of different solutions on the market). By employing PRODAT SENET in the PRODAT BKM-W system it supports either a standalone operation or an integration into existing test & measurement systems and/or infrastructure. The individual measurement system components, especially the sensors are battery operated, and support runtimes of 12h and beyond (longer duration in dependence of the user specific usage cycle are possible). The wireless communication distance with line-of-sight is typically 100m. In typical operation conditions, i.e., in the workshop with metal surroundings and when positioned at the bogies the communication distances can decrease to typically 20 to 30m.

Advantages of a wireless variant in comparison to a cable-based approach are:

- very good calibration characteristics

- Proof of acting forces between wheel and, i.e., brake shoe without moving railcar

- Proof of important additional quantities, i.e., brake system pressures

- During measurement & testing other work on the railcar is still possible (not exclusively blocked)

- long and expensive cables are not required (which usually leads to very long measurement times as an installation and deinstallation is required)

- communication distances up to 100m with line-of-sight

- communication distances in the workshop typically between 20 to 30m (metallic surrounding)

Measurement system components

PRODAT BKM-C and BKM-W follow a modularized system architecture concept. Components are assembled as required and are adapted if required by the customer. Available components are:

- brake force measurement sensors in different construction variants

- repeater units

- sensor for additional binary and analog signals

- gateway units

- charge stations

- measurement PC or mobile

- additional measurement supporting utilities

- unique solutions if required

Promises of a condition based monitoring of railcar brake systemsWear and tear of the brake system are strongly dependent from the usage and the operation conditions – of typical relevance are the time profiles of loads and stresses as well as exceptional seldom events. The typical approach is to design highly durable systems and carry out a maintenance in order to reach or extend the expected system time of live. Hereby the standard is time based maintenance approach. Is nevertheless a condition based approach employed and the full brake system, as well as it critical subsystems are time-discreetly monitored not only the overall safety level is increased but also it is possible to decrease the overall system maintenance costs. As other ,i.e., other competitors state, it is for example possible to extend maintenance intervals if risk evaluation and strategies are employed (i.e., CSM 352/2009/EG).

Nevertheless despite these strong economic advantages PRODATs goal and main driving force of any customer using this system should be to increase the overall security level of their owned and maintained rolling stock.

Examples

|

|

The precise and accurate determination of acting brake forces as well as additional important quantities (i.e., pressures) of the brake system of railcars is of highest importance. The safe transport of persons and goods is of utmost priority. Besides a required test of the brake force system during commissioning such measurement system assisted testing procedures should be carried out during or after maintenance and retrofitting. Although brake systems in good working conditions are the requirements for a safe railcar operation, unfortunately regular time interval-based measurement systems supported checks are still the exception. The typical approach of operational personal carrying out daily operational checks such as a brake system test during standstill or an overall system with a drive and brake approach are not sufficient. Many possible failure modes, especially in system components are not discovered. In addition a condition based maintenance is not possible with these approaches. Furthermore, the more and more increasing pressure for cost efficiency and cost reduction, leads to the questionable practice of increasing the maintenance intervals. If this is solely based on an increase of maintenance interval durations the evolution of critical errors is only a matter of time. The overall safety level of the operated railcar decreases and eventually devastating accidents could occur. Nevertheless, an approach based on independent measurement systems can eventually lead to a win-win situation. The possibility to determine important brake system characteristics (i.e., individual force-time profiles or brake system pressures) permits:

The precise and accurate determination of acting brake forces as well as additional important quantities (i.e., pressures) of the brake system of railcars is of highest importance. The safe transport of persons and goods is of utmost priority. Besides a required test of the brake force system during commissioning such measurement system assisted testing procedures should be carried out during or after maintenance and retrofitting. Although brake systems in good working conditions are the requirements for a safe railcar operation, unfortunately regular time interval-based measurement systems supported checks are still the exception. The typical approach of operational personal carrying out daily operational checks such as a brake system test during standstill or an overall system with a drive and brake approach are not sufficient. Many possible failure modes, especially in system components are not discovered. In addition a condition based maintenance is not possible with these approaches. Furthermore, the more and more increasing pressure for cost efficiency and cost reduction, leads to the questionable practice of increasing the maintenance intervals. If this is solely based on an increase of maintenance interval durations the evolution of critical errors is only a matter of time. The overall safety level of the operated railcar decreases and eventually devastating accidents could occur. Nevertheless, an approach based on independent measurement systems can eventually lead to a win-win situation. The possibility to determine important brake system characteristics (i.e., individual force-time profiles or brake system pressures) permits: The measurement & test system PRODAT BKM-W permits the wireless determination of important brake force system quantities of railcars, such as the acting forces or pressure in the hydraulic brake circuits. If used the number of detectable brake system failure modes is greatly increased, as also individual subsystem functionality can be tested by using an independent and external measurement system (i.e., lockings, pressure losses). A quick maintaining reaction is possible and the overall safety level is increased. The measurement system is based on PRODATs modularized internetworked construction kit and framework PRODAT SENET. It architecture allows very flexible system configurations and besides existing sensors and sensor systems customer specific requirements can be easily solved. Besides using of the force or pressure sensors, digital signals can be acquired if needed. Other possible quantities include environmental workshop conditions such as humidity or temperature. Especially the wireless system approach greatly simplifies the system usage, as typically a large number of fast braking long cables is not required (in difference to a number of different solutions on the market). By employing PRODAT SENET in the PRODAT BKM-W system it supports either a standalone operation or an integration into existing test & measurement systems and/or infrastructure. The individual measurement system components, especially the sensors are battery operated, and support runtimes of 12h and beyond (longer duration in dependence of the user specific usage cycle are possible). The wireless communication distance with line-of-sight is typically 100m. In typical operation conditions, i.e., in the workshop with metal surroundings and when positioned at the bogies the communication distances can decrease to typically 20 to 30m.

The measurement & test system PRODAT BKM-W permits the wireless determination of important brake force system quantities of railcars, such as the acting forces or pressure in the hydraulic brake circuits. If used the number of detectable brake system failure modes is greatly increased, as also individual subsystem functionality can be tested by using an independent and external measurement system (i.e., lockings, pressure losses). A quick maintaining reaction is possible and the overall safety level is increased. The measurement system is based on PRODATs modularized internetworked construction kit and framework PRODAT SENET. It architecture allows very flexible system configurations and besides existing sensors and sensor systems customer specific requirements can be easily solved. Besides using of the force or pressure sensors, digital signals can be acquired if needed. Other possible quantities include environmental workshop conditions such as humidity or temperature. Especially the wireless system approach greatly simplifies the system usage, as typically a large number of fast braking long cables is not required (in difference to a number of different solutions on the market). By employing PRODAT SENET in the PRODAT BKM-W system it supports either a standalone operation or an integration into existing test & measurement systems and/or infrastructure. The individual measurement system components, especially the sensors are battery operated, and support runtimes of 12h and beyond (longer duration in dependence of the user specific usage cycle are possible). The wireless communication distance with line-of-sight is typically 100m. In typical operation conditions, i.e., in the workshop with metal surroundings and when positioned at the bogies the communication distances can decrease to typically 20 to 30m.